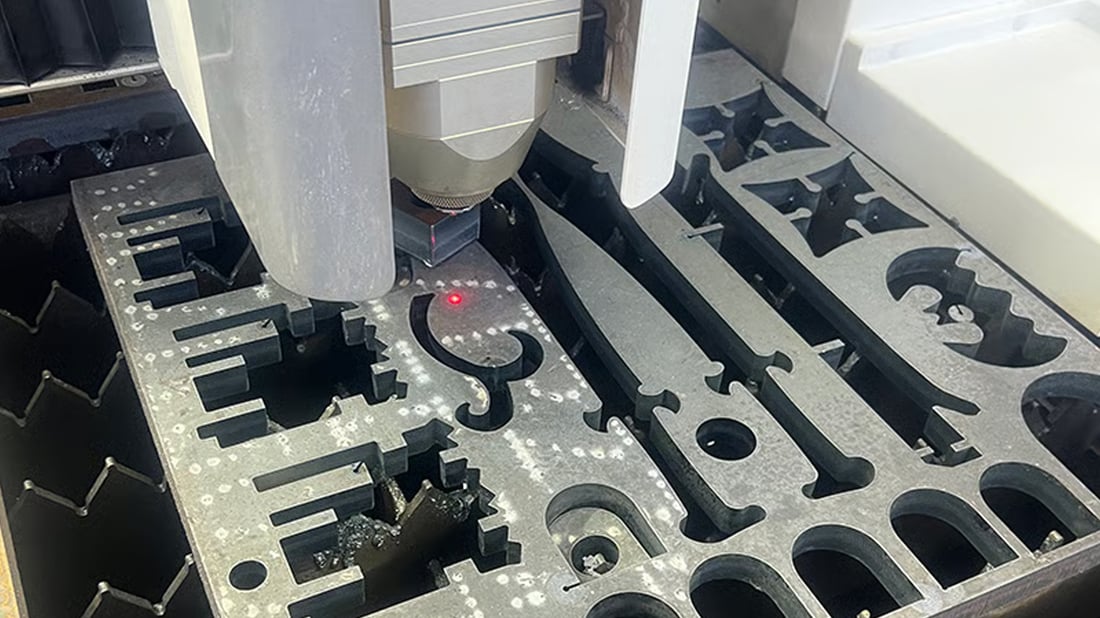

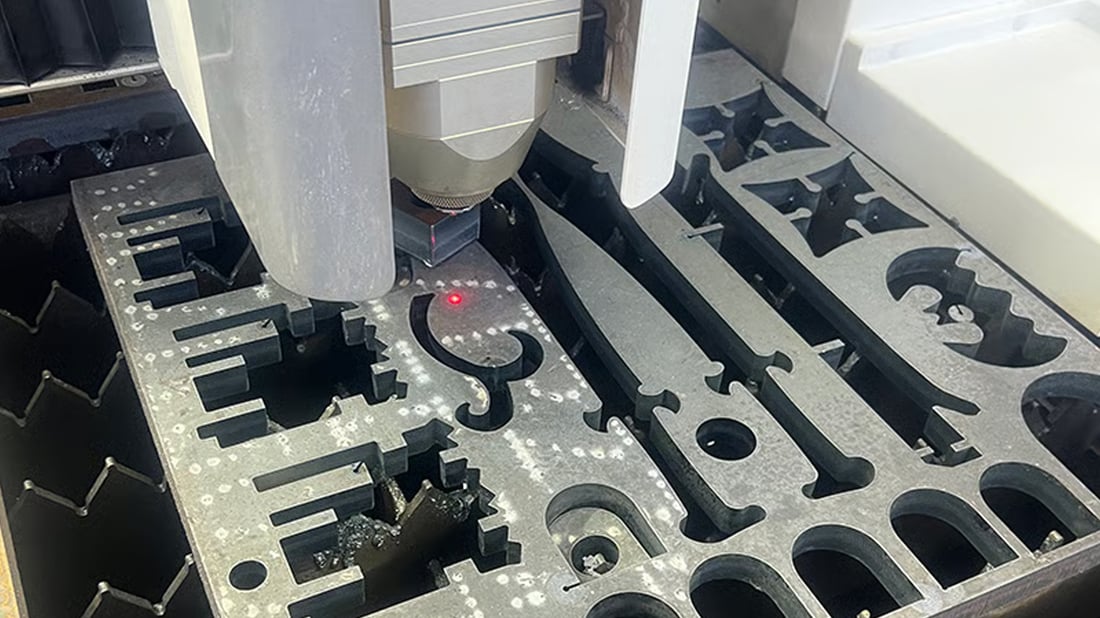

The Basics of Laser Cutting Machines

Laser cutting machines are powerful tools used in various industries for cutting a wide range of materials with precision. These machines use high-powered lasers to melt, burn, or vaporize the material, resulting in clean and accurate cuts. However, the efficiency of a laser cutting machine greatly depends on its energy consumption.

Energy Consumption in Laser Cutting Machines

Energy consumption is a crucial factor to consider when operating a laser cutting machine. The amount of energy used by the machine directly impacts its efficiency and operating costs. By optimizing energy consumption, businesses can reduce their carbon footprint and save on electricity bills.

Importance of Efficiency in Energy Consumption

Efficiency in energy consumption is essential for maximizing the performance of a laser cutting machine. By using energy-efficient components and technologies, businesses can reduce waste and improve the overall productivity of the machine. This leads to cost savings and a more sustainable operation.

Factors Affecting Energy Consumption Efficiency

Several factors can affect the energy consumption efficiency of a laser cutting machine, including the type of laser used, the cutting speed, the thickness of the material, and the machine's cooling system. By optimizing these factors, businesses can enhance the efficiency of their laser cutting operations.

Benefits of Improving Energy Consumption Efficiency

Improving the energy consumption efficiency of a laser cutting machine offers numerous benefits. It reduces operating costs, extends the lifespan of the machine, enhances cutting quality, and contributes to a greener and more environmentally friendly operation.

Technological Advances in Energy Efficiency

With advancements in technology, laser cutting machines are becoming more energy-efficient than ever before. New laser sources, such as fiber lasers, consume less power while delivering higher cutting speeds and accuracy. This enables businesses to achieve more with less energy.

Implementing Energy-Saving Practices

To enhance energy consumption efficiency, businesses can implement various energy-saving practices when operating their laser cutting machines. These include optimizing cutting parameters, maintaining the machine regularly, and investing in energy-efficient components.

Calculating Energy Consumption Costs

Businesses can calculate the energy consumption costs of their laser cutting machines by monitoring their electricity usage and the machine's operational hours. By analyzing this data, businesses can identify areas for improvement and make informed decisions to reduce energy costs.

Future Trends in Energy Efficiency

As sustainability and energy efficiency become increasingly important in the manufacturing industry, the future of laser cutting machines will likely focus on further improving energy consumption efficiency. This includes developing more advanced laser technologies, enhancing automation capabilities, and integrating smart energy management systems.

Conclusion

In conclusion, energy consumption efficiency plays a critical role in the performance and sustainability of laser cutting machines. By prioritizing energy efficiency, businesses can reduce costs, increase productivity, and contribute to a more environmentally friendly operation. Investing in energy-saving technologies and practices not only benefits the bottom line but also helps to shape a more efficient and sustainable future for the industry.

Quote Inquiry

contact us