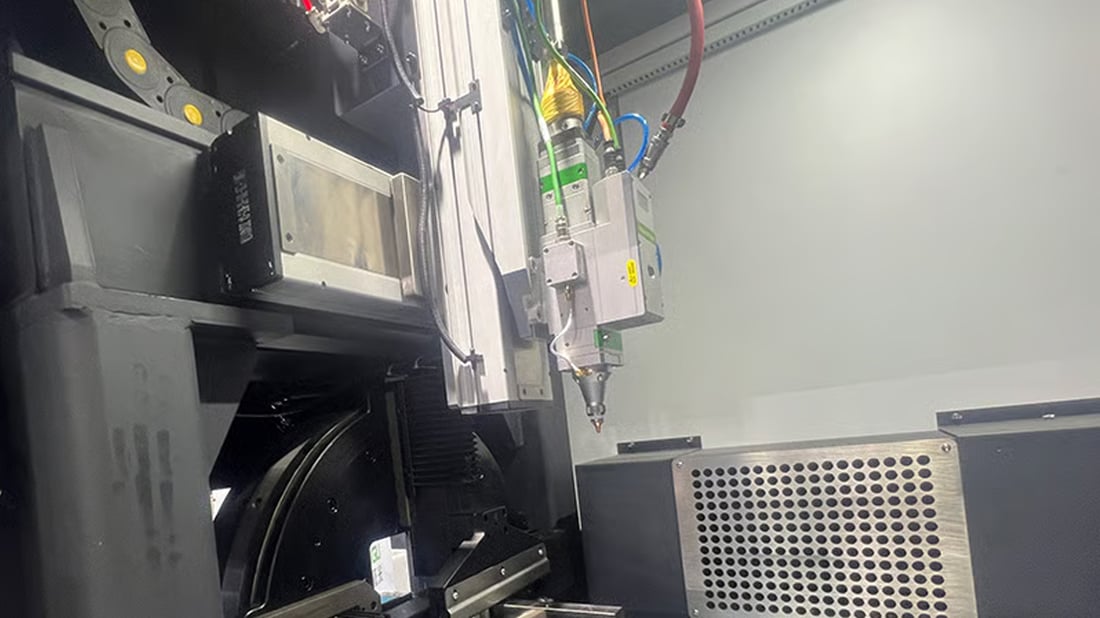

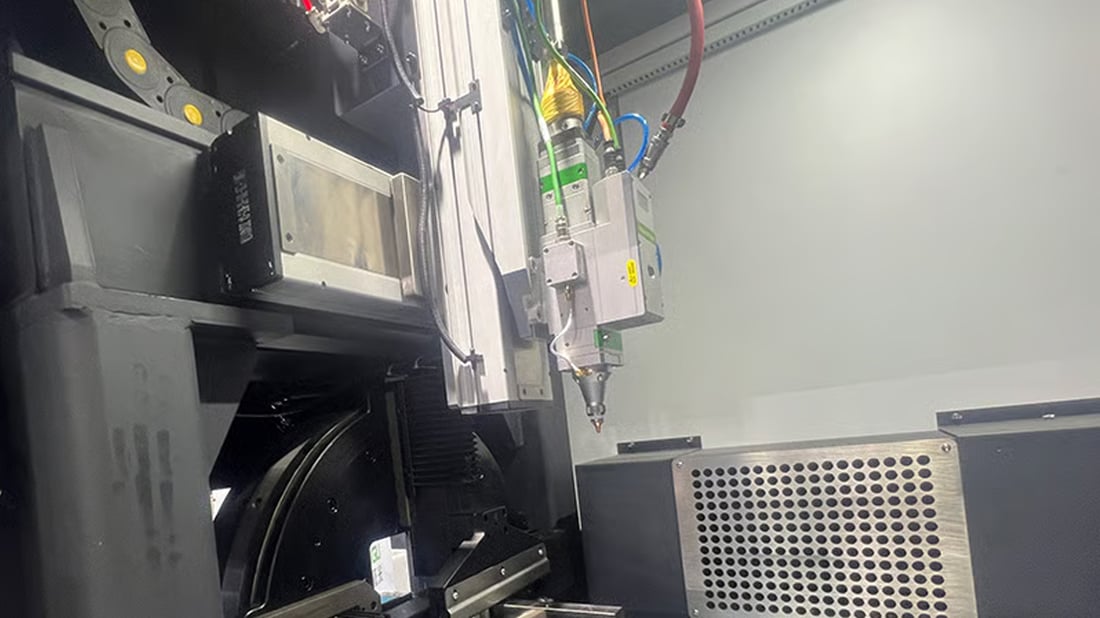

The Advantages of Fiber Laser Technology

When it comes to metal processing speed, fiber laser cutters are the top choice for many industries. These powerful machines use fiber optic technology to achieve incredible cutting speeds, making them ideal for high-volume production environments. Fiber lasers are known for their precision and efficiency, allowing businesses to increase their productivity without sacrificing quality.

Increased Efficiency and Productivity

One of the biggest advantages of using a fiber laser cutter for metal processing is the increased efficiency it offers. These machines can cut through a variety of metals with ease, including stainless steel, aluminum, and copper. With faster cutting speeds, businesses can complete more projects in less time, leading to greater productivity and profitability.

Precision Cutting for Complex Designs

Fiber laser cutters are capable of producing highly intricate and complex designs with extreme precision. This level of accuracy is essential for industries that require tight tolerances and intricate detailing in their metal products. With fiber laser technology, businesses can achieve the perfect cut every time, saving time and reducing material waste.

Cost-Effective Production Solutions

In addition to their speed and precision, fiber laser cutters are also cost-effective solutions for metal processing. By reducing the need for secondary operations and minimizing material waste, these machines help businesses save money in the long run. The quick turnaround times and high-quality cuts produced by fiber lasers make them a smart investment for any metalworking operation.

Enhanced Safety Features

Fiber laser cutters come equipped with advanced safety features to protect both operators and the machine itself. With automated cutting processes and enclosed cutting areas, these machines ensure a safe working environment for employees. Additionally, fiber lasers produce minimal heat-affected zones, reducing the risk of material warping or distortion during cutting.

Optimizing Cutting Speeds for Maximum Efficiency

To maximize metal processing speed with a fiber laser cutter, it's important to optimize cutting parameters for each specific material. By adjusting factors such as laser power, cutting speed, and focal length, businesses can achieve the fastest cutting speeds while maintaining high-quality results. Fine-tuning these parameters is essential for achieving optimal efficiency in metal processing.

Reducing Downtime with High-Speed Cutting

Fiber laser cutters excel in high-speed cutting applications, reducing downtime and increasing throughput for metal processing operations. With rapid cutting speeds and minimal setup times, these machines allow businesses to meet tight production deadlines and handle rush orders with ease. By investing in a fiber laser cutter, businesses can streamline their operations and stay ahead of the competition.

Customizable Automation Options

Many fiber laser cutters offer customizable automation options to further enhance metal processing speed. By integrating robotic loading and unloading systems, businesses can automate repetitive tasks and increase overall efficiency. These automation features enable continuous operation and reduce manual labor requirements, freeing up employees to focus on more complex tasks.

Enhancing Workflow Integration with Software Solutions

Advanced software solutions can help businesses optimize their metal processing workflow and maximize cutting speed with fiber laser cutters. CAD/CAM software allows for seamless design transfer and precise cutting path generation, ensuring efficient production processes. By integrating software solutions with fiber laser technology, businesses can achieve a higher level of control and customization in their metal processing operations.

Future Trends in Fiber Laser Technology

As fiber laser technology continues to advance, we can expect even faster cutting speeds and higher levels of precision in metal processing. Innovations in laser sources, optics, and automation systems will drive the evolution of fiber laser cutters, making them indispensable tools for a wide range of industrial applications. By staying informed on the latest trends and technologies, businesses can stay ahead of the curve and maximize their metal processing speed.

Quote Inquiry

contact us