High rigidity double column design refers to a structural configuration in machine tools where two vertical columns provide enhanced support and stability. Unlike single-column machines, the double column setup distributes forces symmetrically, significantly reducing deflection and vibration. This design is critical in applications requiring high precision and reliability, such as heavy-duty machining and aerospace manufacturing.

Structural Advantages Ensuring Superior Stability

The dual-column layout creates a rigid framework, minimizing deformation under load. High rigidity double column design employs robust materials and optimized geometry to resist bending and twisting forces. This structural integrity ensures consistent machining accuracy, even during high-force operations, enabling operators to achieve tighter tolerances without compromising efficiency.

Improved Load-Bearing Capacity

One of the main benefits of a high rigidity double column design is its increased load capacity. By supporting the spindle and workpiece from two sides, this layout can handle heavier cutting forces and larger workpieces. This capacity advantage extends the machine’s application range, accommodating demanding industrial tasks such as die making, mold manufacturing, and large component fabrication.

Precision Enhancement Through Vibration Damping

Vibrations pose a significant challenge to machining quality. The high rigidity double column design naturally dampens vibrations by providing balanced support and reducing resonant oscillations. This damping effect is crucial for maintaining surface finish quality and dimensional accuracy, ensuring that even complex shapes are produced with minimal deviation from design specifications.

Optimized Tool Path Accuracy

With a high rigidity double column design, tools follow more precise paths due to minimized structural deflection. This accuracy is essential for contouring, fine milling, and multi-axis machining where every micrometer counts. The design reduces errors associated with tool runout and backlash, resulting in enhanced productivity and reduced scrap rates.

Enhanced Thermal Stability

Thermal expansion can distort machine components and affect machining precision. The symmetrical nature of a high rigidity double column design helps maintain thermal equilibrium by evenly distributing heat stresses across the structure. This balanced thermal profile prevents localized distortions, supporting long-term precision and extending the overall machine lifespan.

Facilitating Large Workpiece Machining

The robust framework of a high rigidity double column design enables the machining of large or unusually shaped components. The expansive working area between two columns facilitates the mounting and movement of sizeable parts with ease. This capability is particularly beneficial in industries like aerospace and energy, where sizable or complex components are common.

Maintenance and Durability Benefits

High rigidity double column machines often exhibit increased durability and require less frequent maintenance. The balanced structural design reduces wear on critical components, especially guideways and ball screws. Additionally, the framework’s integrity allows for better protection against dust and coolant contamination, contributing to longer operational cycles and reduced downtime.

Cost Efficiency via Productivity Gains

Though machines with high rigidity double column design may have a higher upfront cost, their ability to maintain precision under heavy loads leads to productivity gains and lower reject rates. Enhanced machining stability shortens cycle times and allows for the use of higher cutting parameters. This efficiency translates into reduced operational costs and faster return on investment.

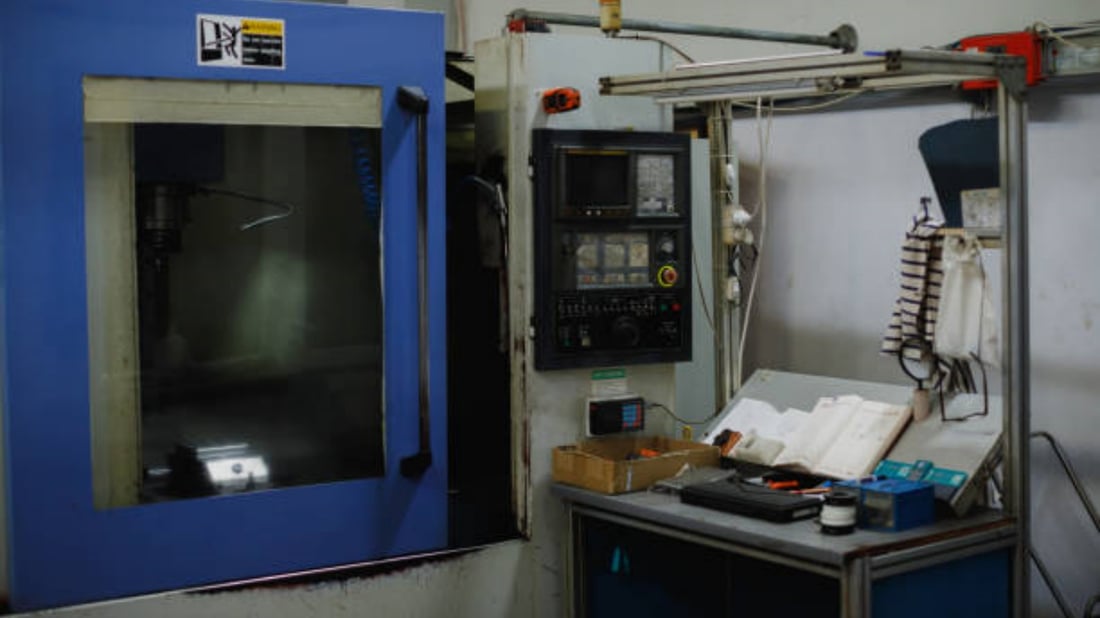

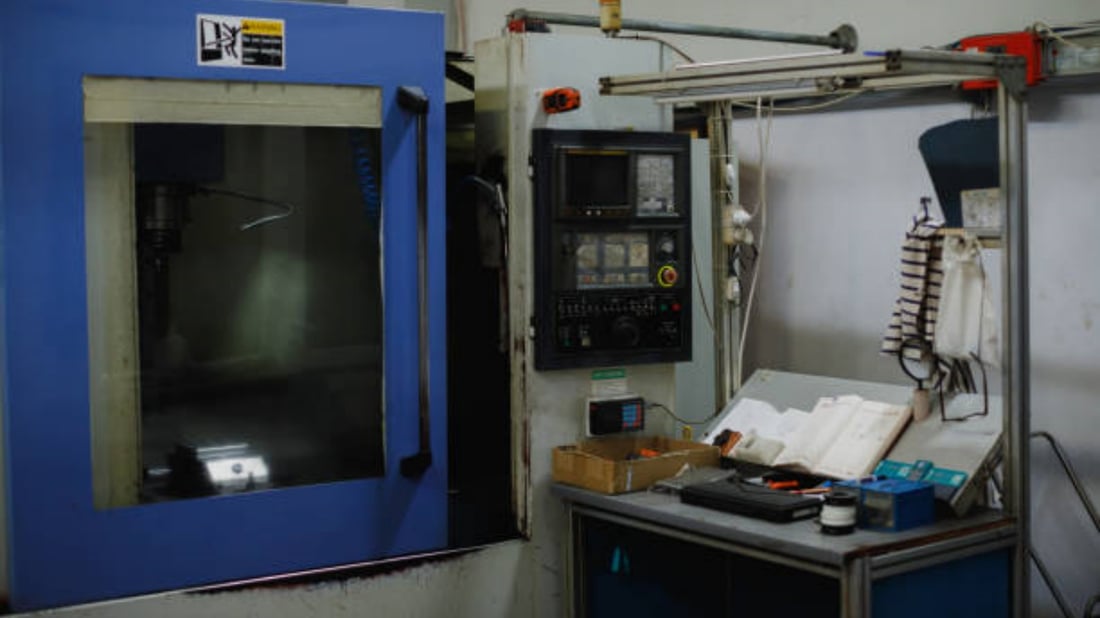

Future Trends and Technological Integration

Advancements in materials, such as composite reinforcements, and integration with smart sensors further elevate the capabilities of high rigidity double column design. These innovations enable real-time monitoring of machine deflection and wear, facilitating predictive maintenance. Moreover, coupling this design with CNC and automation technologies expands its application potential in Industry 4.0 manufacturing environments.

Quote Inquiry

contact us